Stator Winding Assembly

Stator Winding Assembly Specification

- Surface Treatment

- Anti-corrosive Coating

- Part Type

- Motor Internal Component

- For Use In

- Electric Motors, Generators

- Model No

- SWA-22

- Method

- Precision Coil Winding

- Temperature Range

- -20C to 120C

- Vehicle Type

- Industrial / Commercial Equipment

- Working Life

- Minimum 10,000 hours

- Connecting Type

- Terminal Connector

- Load Capacity

- 3.5 kW

- Material

- Copper Wire & Insulated Steel Core

- Finish

- Smooth & Glossy

- Size

- Customizable

- Color

- Copper & Silver Grey

- Noise Level

- <45 dB

- Corrosion Resistant

- Yes

- Dimension (L*W*H)

- 165 mm x 140 mm x 120 mm

- Product Type

- Stator Winding Assembly

- Lubrication Type

- None Required

- Operating System

- AC/DC Motor Compatible

- Weight

- Approx. 1.2 kg

About Stator Winding Assembly

Versatile Applications & Distinct Advantages

Our Stator Winding Assembly finds exceptional utility in electric motors and generators, serving both general and specialized industrial equipment. Thanks to its universal motor series compatibility, users benefit from enhanced operational versatility, reliable current capacity up to 8 Amp, and a robust, corrosion-resistant build. The grandiose double-layer lap winding ensures steady performance for a wide spectrum of machines, making it equally suitable for new installations or efficient replacements in various domains.

Sample, Payment Terms & Domestic Distribution

Packing & Dispatch of the Stator Winding Assembly is executed using protective foam boxing to safeguard integrity during transportation. Sample units are available for evaluation prior to bulk orders. Flexible outlay options include multiple payment terms to suit diverse customer needs. We efficiently handle distribution throughout India's main domestic markets, ensuring clients receive their orders promptly and securely, with consistent focus on quality and customer satisfaction at every stage.

FAQ's of Stator Winding Assembly:

Q: How does the Stator Winding Assembly support both AC and DC motor systems?

A: The SWA-22 is engineered for universal application, meaning it is compatible with AC and DC motor systems. Its terminal connector and wiring flexibility ensure seamless integration across different motor types.Q: What makes this Stator Winding Assembly highly durable and reliable?

A: Featuring a laminated silicon steel magnetic core, anti-corrosive coating, and double layer lap winding, the assembly delivers impressive resilience. These factors help guarantee reliable, long-term operation and a minimum working life of 10,000 hours.Q: When is a sample of the Stator Winding Assembly available for evaluation?

A: Sample units can be requested at any stage before finalizing bulk orders, giving customers ample opportunity to assess quality, compatibility, and performance.Q: Where is this product distributed domestically within India?

A: We distribute across major domestic markets throughout India, and can arrange transportation and packing to reach customers in every key industrial region.Q: What advantages do users gain from the assembly's universal motor compatibility?

A: Users benefit from streamlined inventory needs, simplified replacements, and adaptable installation across a wide variety of generators and motors, making it a cost-effective choice for varied operations.Q: What packaging ensures safe and secure delivery of the stator assembly?

A: Each assembly is packed in protective foam boxes, providing excellent cushioning during packing, transit, and dispatch, which ensures the product remains in pristine condition upon arrival.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Alternator Stator Assembly Category

Bearing For 6202

Corrosion Resistant : Yes

Color : Silver

For Use In : Automobile, Electric Motors, Machine Tools

Surface Treatment : Polished

Part Type : Bearing

Material : Chrome Steel (GCr15)

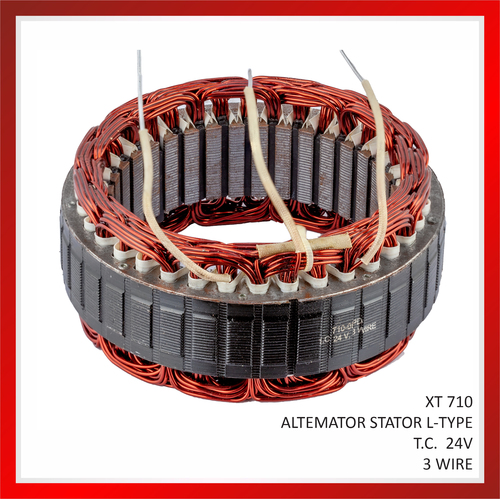

Alternator Stator L Type

Corrosion Resistant : Yes

Color : Silver and Copper

For Use In : Automotive Alternators

Surface Treatment : Varnish Coated

Part Type : Stator Core Assembly

Material : Copper Winding, Laminated Steel Core

Alternator Winding Assembly

Corrosion Resistant : Yes

Color : Copper Red with Insulation

For Use In : Automotive Alternators

Surface Treatment : Insulated with Heat Resistant Coating

Part Type : Electrical Winding

Material : Copper/Aluminum (as per application)

STATOR WINDING ASSEMBLY

Corrosion Resistant : Yes

Color : Copper Brown, Red Insulation

For Use In : Automotive Alternators, Generators, Motorcycles

Surface Treatment : Epoxy Coated, Varnished

Part Type : Electrical Component

Material : Copper Wire, Laminated Iron Core

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry